Overview

|

Applicable Industries |

Machinery Repair Shops, Retail, Construction works |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Not Available |

|

Warranty of core components |

3 months |

|

Condition |

New |

|

Construction |

Cartridge Filter |

|

Place of Origin |

China |

|

Brand Name |

BOSHIDE |

|

Dimension(L*W*H) |

33.5*33.5*54.5 |

|

Weight |

4.05 KG |

|

Warranty |

3 months |

|

OEM NO |

P777868 AF25454 53C0253 |

|

Model |

EC360 ZAX450 PC450 |

|

Application |

use for excavator |

|

Type |

air filter |

Products Feature

1.We use imported depth type filter material,circular pore structure,gradient filter,can intercept granule furthest, to extend the service life.

2.We use high tech support materials.High tech support materials can not only play the role of support filter, material and avoiding compressive deformation,but also protect the materials from being damaged during processing.

3.We also use the special spiral wrapping belts,so that filter layers can be connected firmly.Stationary pleated distance ensures the uniform flow when fluid penetrating the filter layer.Not only improving pressure drop,but also extending service life.

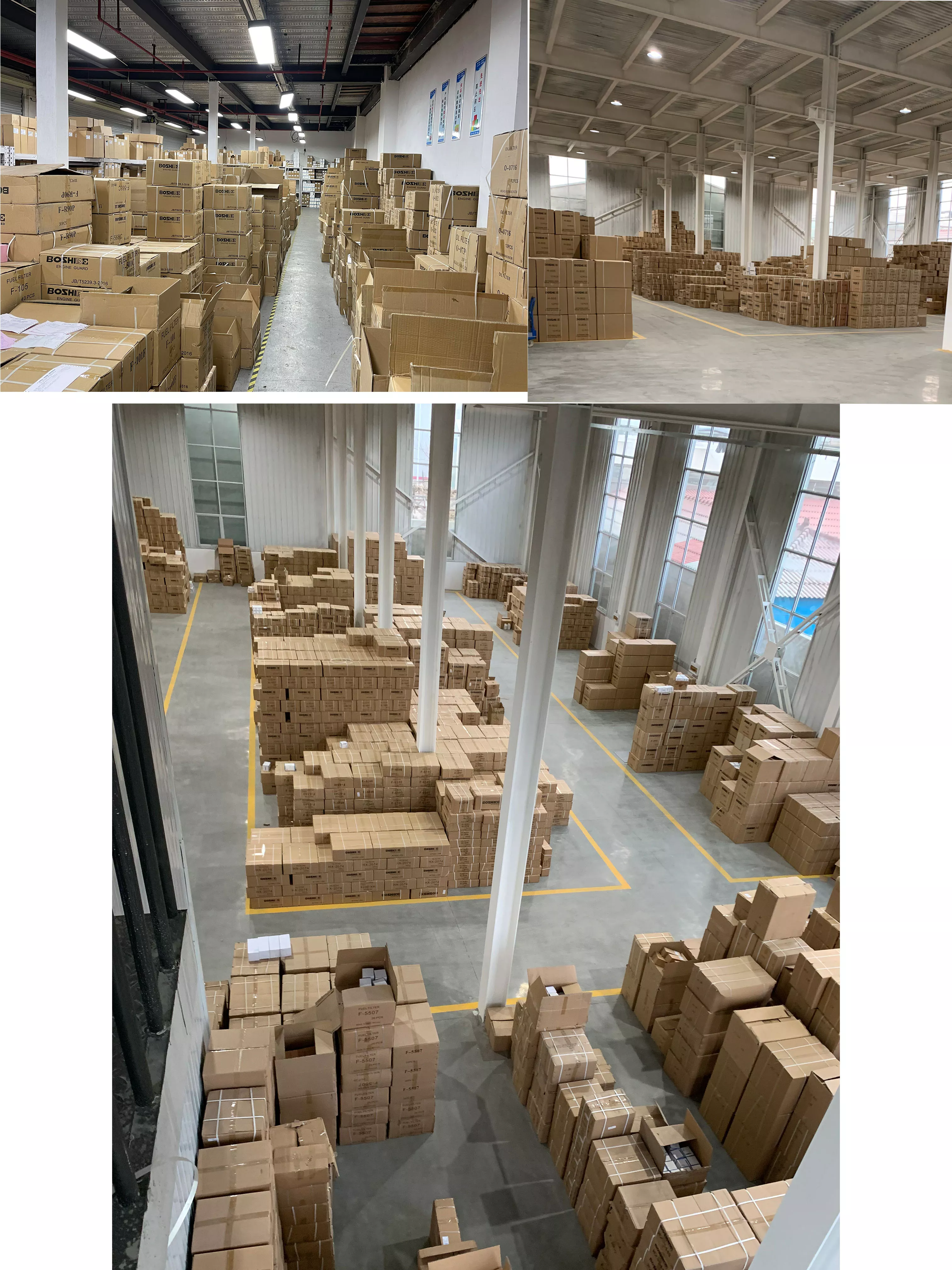

Company Profile

BOSHIDE is our own brand, we have our own R&D team,manufacturer,brand marketing system, At present,our products have been in several countries in South east Asia,North Africa,South America,Middle East,Eastem Europe has a point of sale or agent.

We have 2000 kinds of products,the vastmajority of applications in engineering machinery or truck. Our main products are Air Filter,Oil Filter,Fuel Filter,Hydraulic Filter,Hydraulic Pilot Filter,Coolant Filter,Spin-On Hydraulic Filter and Filter Head this industry,our quality is Top10,our all main material is Ahlstrom paper imported from Korean and HV paper imported from American.

We accept brand customizatio,Our company has a professional sales team and aperfect sales network.

We will combine your needs with theactual situation to provide the best quelity products and the most perfect after-sales

service for you.Look forward to our cooperation.

Packing and Shipping

1. Our goods are by air/sea/express (DHL/FEDEX/TNT/UPS/EMS).

2. Once we receive payment confirmation, we will ship within 7 days.

3. Our packing is standard packing or other according to your requirements.

4. We will check and test the product before shipment, and provide the picture to our customers for confirmation.

FAQs

How to replace the filter element?

1. Replace the filter element of single barrel pre-filtering device:

a. Close the ball valve of oil inlet and open the upper end cover. (Aluminum alloy type upper end cover needs to be gently pried open from the side notch with a flat screwdriver);

b. Unscrew the drain port plug wire and drain the dirty oil;

c. Loosen the fastening nut at the upper end of the cartridge, the operator wears oil-proof gloves to hold the cartridge and remove the old cartridge vertically;

d. Replace the new cartridge, gasket the upper end seal (the lower end has its own gasket) and tighten the nut;

e. Tighten the drain port plug wire, cover the upper end cover (pay attention to the gasket) and put on the new cartridge. good sealing ring), and tighten the bolt.

2. Replace the filter element of the double-barrel parallel pre-filtering device:

a. Close the oil inlet valve of the filter on the side where the filter element needs to be replaced first, close the oil outlet valve after a few minutes, then unscrew the end cover bolts and open the end cover;

b. Open the drain valve to thoroughly drain the dirty oil and prevent the dirty oil from entering the clean oil chamber when replacing the filter element;

c. Loosen the fastening nut at the upper end of the filter element, and the operator wears oil-proof gloves to hold the filter element and remove the old filter element vertically upward;

d. Replace the new cartridge, gasket the upper end seal (the lower end has its own gasket) and tighten the nut;

e. Close the drain valve, cover the upper end cover (pay attention to the gasket) and fasten the bolts.

f. Open the oil inlet valve first, then open the exhaust valve, close the exhaust valve immediately when the oil comes out of the exhaust valve, and then open the oil outlet valve; then operate the other side of the filter in the same way.